Dry Steam vs. Wet Steam: Which is Better for Ice Dam Removal?

At least between the sorts of people who remove ice dams professionally, steam has long been a hot topic. The disagreement is over which type of steam is better for removing ice dams: dry steam or wet steam? Which one is safer? Which one is faster? Is the other one bad? But what could have been an honorable jousting match settled by “Let customers decide what’s best” has instead turned into the “dry-steam” team misleading customers about the “wet-steam” people. If you understand a couple of basic differences between dry steam and wet steam, you’ll understand how effective (or ineffective) each one can be in ice dam removal, depending on the situation and its particulars. You’ll also understand how honest any given ice dam removal company is and be in a better position to know exactly what you need if you’ve ever got an ice dam emergency. Spoiler alert: Anyone using steam is using wet steam, by default.

Most ice dam removal companies also know the difference between dry steam and wet steam, but they assume you don’t, or that you won’t do your homework. They figure they can make money by telling you a two-part whopper: they’ll say the other companies don’t use steam, and they’ll say that they “only use dry steam” or “use 100% dry steam.” Not only is that scientifically false, but it’s also purposely misleading.

The reality is that all true steam used for ice dam removal is wet steam, as dry steam is more gas-like. The water droplets in wet steam help it melt ice in a more-targeted and efficient way. We’ll explain all of that more in a minute, but if you take away nothing else today, just remember that one point. Ice dam removal providers and others who may say otherwise either misinterpret scientific facts, skew the facts, lack common sense, or have been lied to by whomever sold them their steamer. In our experience, a combination of all four is usually the problem.

What Is Steam?

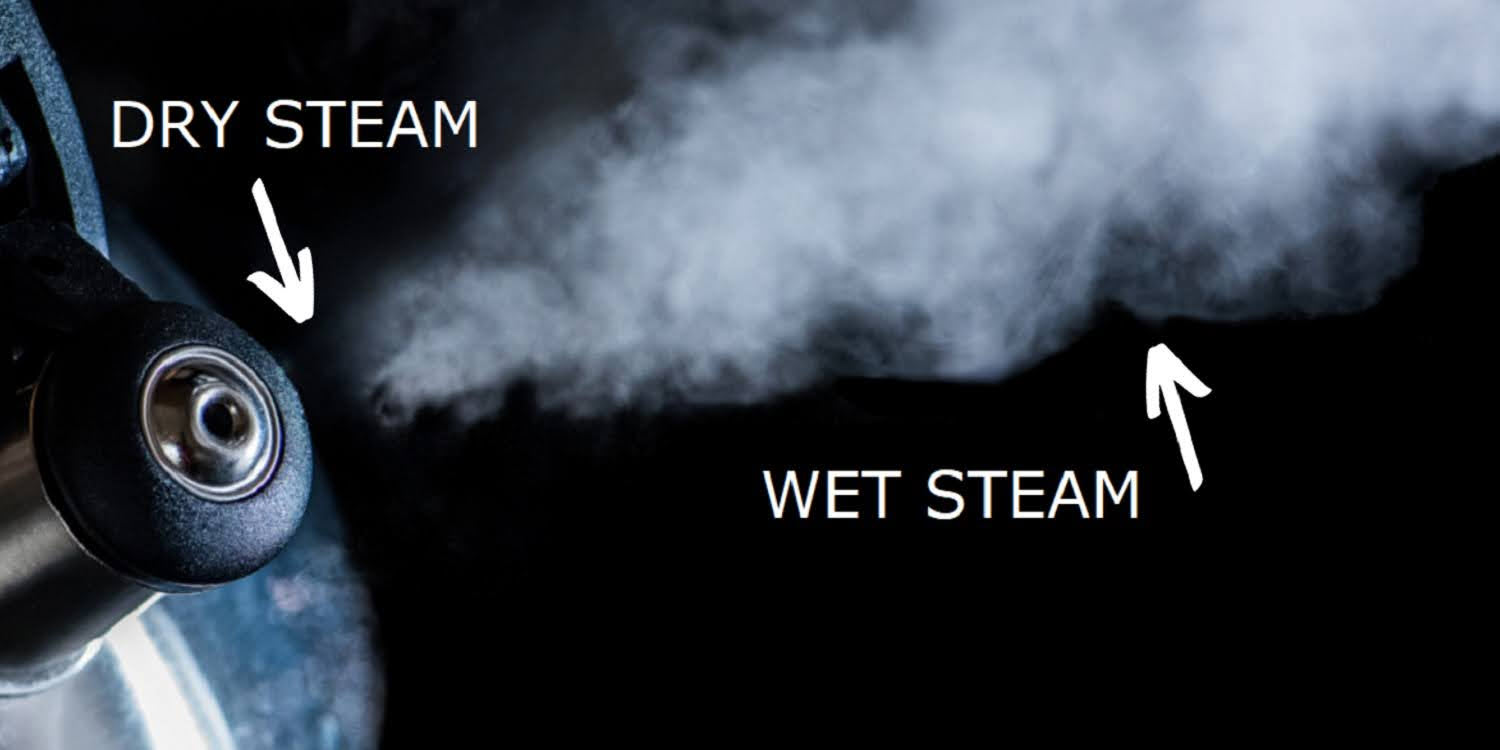

Steam is the byproduct of water that’s been heated to or beyond its boiling point ( 212°F at sea-level). As the water heats, the liquid first becomes an aerosol (wet steam) and eventually may be vaporized into a gas (dry steam). This occurs when you have a heat source (e.g. a diesel-fired burner, in this case). In other words, the hotter the steam, the smaller and more dispersed the airborne water particles are.

Steam also gains pressure as it heats up. Picture a stovetop tea kettle. As the burner heats the water to 212°F, it begins to boil, changing some of the liquid into aerosolized steam (microscopic droplets are still present). As the temperature keeps rising, the pressure in the kettle also intensifies, leading to even more steam. When the internal pressure and heat cross certain thresholds, it’s too great to stay contained and it escapes the kettle’s spout as a high-pressure steam jet.

What Are The Different Types of Steam? Wet Steam vs. Dry Steam

In the world of ice dam removal, there are only two types of steam: wet steam and (theoretically) dry steam. We can’t provide the exact temperatures at which wet steam becomes dry steam, partly because pressure and elevation (relative to sea level) also factor in. Also, we’re not scientists, and this isn’t meant to be a scientific paper. Even so, we can get into hard facts and wheel out some basic scientific principles. We’ll provide exact numbers (in Fahrenheit) when we can, and the rest of the time we’ll mark generally established statements and estimates with asterisks (*).

Wet Steam Definition & Qualities

Wet steam is what most of us picture when we think of steam. It’s also what experienced and professional ice dam removal companies use to melt ice dams and frozen gutters, because it contains a lot of latent heat. Because the water droplets are almost hot enough to become gaseous, those droplets are extremely hot, and because they haven’t yet turned into a gas, they can be directed towards the ice dam without simply drifting away in the wind.

Wet steam is produced when water is heated to 212°F up to around 250°F*. It’s called “wet” because it hasn’t absorbed enough energy to become fully gaseous (AKA dry steam). Wet steam is an aerosol, meaning that it has some moisture content present, mostly in the form of hot microscopic water droplets. (When aerosolized water has reached what’s called the vapor–liquid equilibrium (VLE) it becomes hot vapor.) Those tiny droplets are airborne. A blast of wet steam is a blast of both superheated air and superheated water droplets.

Reaching that 212°F – 250°F temperature range is critical to steam production, because if you don’t get your water hot enough to produce wet steam, you’ve only got hot water. Worse yet is that hot water isn’t even as hot as it could be. Hot water alone (less than 212°F) is not ideal for most ice dam removal applications because it tends to be too wet, can be too abrasive on your roof’s shingles when over-pressurized, and oftentimes (depending on the exact temp) can’t transfer enough heat to the ice before it cools down. Although it can remove an ice dam, it’s often prohibitively messy and time-consuming, and the amount of water needed may cause unavoidable secondary problems (e.g. basement flooding, increasing the flow rate of an existing roof leak, etc.).

What happens when you heat the water beyond that wet-steam range (about 250°F*)? You start getting dry steam.

Dry Steam Definition & Qualities

The lines between dry steam and wet steam can be subtle and confusing. In general, steam that’s heated beyond 250°F* has become a gas, and so it becomes “dry steam”. It is no longer an aerosol, with water droplets suspended in the steam. In dry steam, the water molecules have been broken up and scattered throughout the air. That is, the moisture content is less concentrated and more gaseous.

At least theoretically, dry steam isn’t moist at all – hence its name “dry steam.” But dry steam only remains moisture-free in controlled environments, like in science labs, industrial sanitation systems, etc. Maintaining an operational flow of 100% dry steam is not possible in a practical sense.

Unlike the pressurized hot-water example we discussed with wet steam, dry steam cannot be too rough on your roof’s shingles because it’s a gas, and by nature, a gas cannot be abrasive. Though that might sound nice and gentle on your roof, the downside is that because it’s a gas, it cools almost instantly upon leaving the nozzle. Not only does that diminish whatever melting power it may have had, but we also can’t direct or harness the steam the way we can with wet steam. Whereas wet steam retains its heat much longer and gets blasted out of a steamer tip, dry steam cools quickly and more or less floats out under very little pressure, which means (for one thing) that it takes forever to melt an ice dam. Theoretically, dry steam could melt an ice dam, but it would not be the most efficient or effective option. It would be like kneading dough with a soft rubber spatula, rather than with your hands.

At least in the context of ice dam removal, one way to think of dry steam is as lost energy: the steamer unit expends energy (i.e. burning excess diesel or kerosene) to make the steam hotter and hotter, but all of that excess heat is lost during its journey from the boiler, through the steam hose, to the nozzle. Most of the energy used to make dry steam is wasted.

When Does Wet Steam Become Dry Steam?

Wet steam turns to dry steam at around 250°F*, generally. But it’s not usually an instant change, like a switch being flipped. Even in our tea kettle example, you can see both dry steam and wet steam at the same time. Some of the water vapor may be a little cooler than that roughly 250°F threshold, and some will be hotter. Due to both wet steam and dry steam hovering in that 250°F range, you can see how they become harder to tell apart when not in perfectly controlled environments.

Microscopic Water Droplets Help Transfer Heat Better

Let’s say we have a regular clothing iron with a steaming function. If we raise that iron and hit the “steam” button it would produce steam. We’ll get a nasty burn if we’re a couple of inches away, but if we’re a couple of feet away it will just feel warm, and perhaps it won’t feel like anything at all. The heat from that steam will disperse quickly.

Next, let’s imagine we knock over that iron and accidentally spill a few drops of water onto our legs or feet. Even though the water has traveled farther – at least a couple of feet – when those very small hot water droplets hit your skin you’ll recoil in pain because they’re still hot. The heat is still concentrated. That’s the power of heat transference (and heat retention) with water droplets.

Now join me on your roof where I have to remove a 2-foot block of ice spanning the entire length of your roof and it’s in the single digits with a strong wind. Which do you think will melt ice dams more effectively? As you probably guessed, the wet steam with scalding microscopic water droplets wins every time. The dry-steam vapor just floats away in the wind, cools almost instantly, and only looks powerful. It’s long on bark and short on bite.

Wet Steam Has More Directed Kinetic Energy

Another reason wet steam often outperforms dry steam is that it retains more kinetic energy. That energy allows our ice dam removal techs to apply more controlled pressure and placement when removing ice dams than if they used dry steam.

Unlike dry steam, aerosol water droplets in wet steam have more heft – more matter that we can control and use. Dry steam mostly floats away after it exits the nozzle. While kids and customers love seeing those giant plumes of white steam, we look at them as lost energy that’s not melting your ice dam.

While dry steam could melt an ice dam it would take much longer and be less directed or precise. The efficiency of wet steam translates to lower costs because we’re at your home for less time. With wet steam, we can melt your ice more quickly.

The Long Journey from Dial to Ice

Many ice dam removal companies trash-talk wet steam without even understanding it, let alone understanding how it’s more effective. Worse, most of them have been so bamboozled by the company that sold them their steamer that they don’t even realize they are the proverbial pot calling the kettle black. They are using wet steam and don’t even realize it. Whatever their original intentions, they have become so obsessed with theoretical steam temperatures and what temperature their “dial” points to that they ignore all the other factors that cause all steam – wet or dry – to cool down. It’s like only caring about what the highest number on your speedometer is, without any thought as to whether the car can reach that speed or how it performs if it does.

Even our in-house-customized beast of an ice dam steamer, Steamzilla™ can reach 300°F (and beyond) at the heating coil output, but the steam will leave the nozzle at a much lower temperature. The steam that makes contact with the ice is even cooler yet. That’s true of our steamers and for everyone else’s as well.

Here are a couple of overlooked factors that cool down everyone’s steam:

Hose Length: Ice dam removal pros do not lug their heavy machine up your ladder onto the roof. It’s just not practical, physically possible, or needed. We all use hoses that run from the steamer in our trucks. Those hoses can run 50-300 feet. There’s always some heat loss when a fluid (or gas) needs to travel through a hose that’s lying in snow for 50+ feet. If a steamer makes 300°F steam at the heating coil, it comes out roughly in the 215°F – 250°F range (yes, we’ve measured that). That’s plenty hot to melt an ice dam, but the temperature loss is real, substantial, and unavoidable.

Outside Temperatures: We’ve been exposed to a variety of temperatures over the years. A nice balmy day may be 15°F, and a tough day (or night) might be -30°F – more than 60 degrees below freezing. (No, that’s not only here in Minnesota!) Whatever the ambient temperature is when we’re on your roof also factors in. When the hose isn’t lying in snow, the hose is hanging in extremely cold air.

The hard reality is simple: unless you’re thawing an ice dam directly near your heating coil with a 10-foot hose, the steam will be at a much lower temperature than it was at the point of origin. And that’s a good thing, too, because most homes in America have asphalt shingles. While these work great against Mother Nature, they’re not as resilient when exposed to extreme temperatures, simply because they’re largely made of tar. In fact, asphalt shingles can (and do) melt when an extreme heat source, say “300°F of dry steam,” is left stationary for too long. Having wet steam in the low-to-mid 200-degree range is ideal and much more gentle on your roof. Plus, it allows us to work those ice dams out of your gutters without worrying about burns.

The “hotter the better” mentality is a flawed one, and that’s why you shouldn’t trust a company that claims to have “the hottest dry steam.” Maybe it is 300°F at the heating coil, but it’s not nearly that hot at the nozzle. It’s just a marketing sleight of hand. You can’t trust any company touting the extreme temp of their steam, or trust someone who is fixated on the temperature gauge on the steamer.

We’re transparent about it: our steam will reach your ice dams as aerosolized wet steam from 215°F to 250°F. We’ve found that a hint of vapor is the most reliable indicator that you’ve reached optimal wet steam for the most efficient and effective melting of ice dams. You get the heat-retention of the moisture droplets, without heating them so hot that they can’t retain heat anymore.

You can see in the video below that we’re able to remove ice dams in a surgical way, with every bit of steam working toward the same purpose.

Conclusion #1: Wet Steam is Best for Ice Dam Removal

Though you can perform ice dam removal with either wet steam or dry steam, wet steam performs better in the field. While both levels of steam can sit around 250°F, wet steam has water droplets present that allow for more heat to be transferred, and in a more directed manner.

Conclusion #2 Ice Dam Removal Companies Confuse Customers about Wet Steam and Dry Steam

Despite whatever’s claimed, dry steam is not what comes out of the nozzle. Many ice dam removal companies say they use “100% dry steam,” but we know that even when dry steam is created at the burner, it is no longer dry steam at the nozzle (where it’s being emitted). Even if you could reach an ice dam with dry steam (with an impractically stubby hose), unless you were in a controlled chamber, the dry steam emitting out the nozzle would become wet steam in the blink of an eye due to the frigid ambient temperatures.

We know that a huge amount of heat is lost when steam is being transported through long hoses, but those long hoses are necessary on every job. But even if we were able to retain enough heat to have 100% dry steam come out of the nozzle, and we could direct that dry steam exactly where we wanted it, dry steam simply doesn’t transfer heat as well. Dry steam starts off hotter by definition, but cools down much more quickly than wet steam. The whole idea of steam is to transfer the maximum amount of heat to the exact spots you want to melt. Most of the heat of dry steam gets sucked out before it reaches the ice, and IF any heat reaches the nozzle, it’s instantly cooled before it even impacts the ice.

Meanwhile, wet steam retains more of its heat. The little water droplets carry more heat and force as they smack into the ice, both heating it and breaking it up on a microscopic level.

As in most areas of life, it’s possible to overdo something. You want steam: not water, but not gas. A balance is ideal. Most ice dam removal professionals don’t strike the balance. Some of them know what works best, choose not to provide it, accuse their competitors of doing it the wrong way, and never explain to you exactly how. Other ice dam removal companies may mean well, but were lied to by the manufacturer of the steamer units they bought.

If you speak with a company that claims to use only dry steam, and claims that it’s better, by all means, hear them out. Just ask them to explain the physics behind why their steam is supposed to work well on an ice dam. If they can’t or won’t, or if they just keep repeating “the hotter, the better,” then they’re probably trouble.